If you own or operate a construction supply outlet, you may be eligible to supply ICCONS range of construction fastening supplies at wholesale prices!

- Log In

- Sitebox

- Contact

- Find a dealer

-

Anchoring

Anchoring

- Screw Bolts

- Thru-Bolt Stud Anchors

- FM753 - Heavy Duty Through Anchors

- ATS-EVO Heavy Duty Anchors

- STA-EVO Heavy Duty Anchors

- Hangerz

- Drop-In Anchors

- Suspension and Tie Wire Anchors

- Sleeve Anchors

- Panel Brace Anchors

- Friulsider Nylon Anchors

- Metal - Light Duty

- Nylon - Light Duty

- Plasterboard and Hollow Cavity Wall Anchors

- Plastic Wall Plugs and Spaghetti

- Strike Anchors

-

Pipe Clamps

Anchoring

-

Cast-In Anchors

Anchoring

- Shims and Other

-

Hollow Section Fittings

Anchoring

-

Adhesives

Adhesives

-

Nailing

Nailing

- Rivets

-

Screws

Screws

-

Self Drillers

Screws

- Self Drilling Bugle Head

- STET Aesthetic Architectural Tamper Resistant Screw

- Self Drilling Button Head

- Self Drilling Countersunk Head

- Self Drilling Countersunk Wing

- Self Drilling Flathead

- Self Drilling Hex Head

- Self Drilling Mushroom Head

- Self Drilling Pan Head

- Self Drilling Trade Packs

- Self Drilling Trade Tubs

- Self Drilling Wafer Head

- Self Drillers

- Type 17

- Collated

-

Decking

Screws

- Needle Point

- Chipboard

- Cyclonix

-

Painted Screws

Screws

- Painted - Needle Point Hex Head

- Painted - Self Drilling Button Head

- Painted - Self Drilling Flathead

- Painted - Self Drilling Hex Head

- Painted - Self Drilling Multiseal - 14 Gauge

- Painted - Self Drilling Trade Packs

- Painted - Self Drilling Trade Tubs

- Painted - Self Drilling Wafer Head

- Painted - Type 17 Cyclonix - 14 Gauge

- Painted - Type 17 Hex Head

- Painted Screws

- Muro - Collated Screw Solutions

-

Self Drillers

-

Drilling

Drilling

- Drilling - SDS Plus

- Drilling - SDS Max

- Dustless Drilling

-

Drilling Power Tool Accessories

Drilling

- Countersinking / Pre-Drilling Accessories

- Impact Fastdrive - Bit Holders

- Impact Fastdrive - Bit Kits

- Impact Fastdrive - Insert Bits

- Impact Fastdrive - Nut Setters

- Impact Fastdrive - Power (Double Ended) Bits

- Impact Fastdrive - Power Bits

- Standard Fastdrive - Bit Holders

- Standard Fastdrive - Insert Bits

- Standard Fastdrive - Nut Setters

- Standard Fastdrive - Power Bits

- Impact Sockets

- Drill Attachments

- Tile Bits

- Ratioquick Core Bits and Accessories

- Drilling Power Tool Accessories

- Metal / Wood / Concrete Kits

-

Diamond

Diamond

-

Tools

Tools

-

Other

Other

- Support & Downloads

- Partners

- Careers

- About

Dealer Login

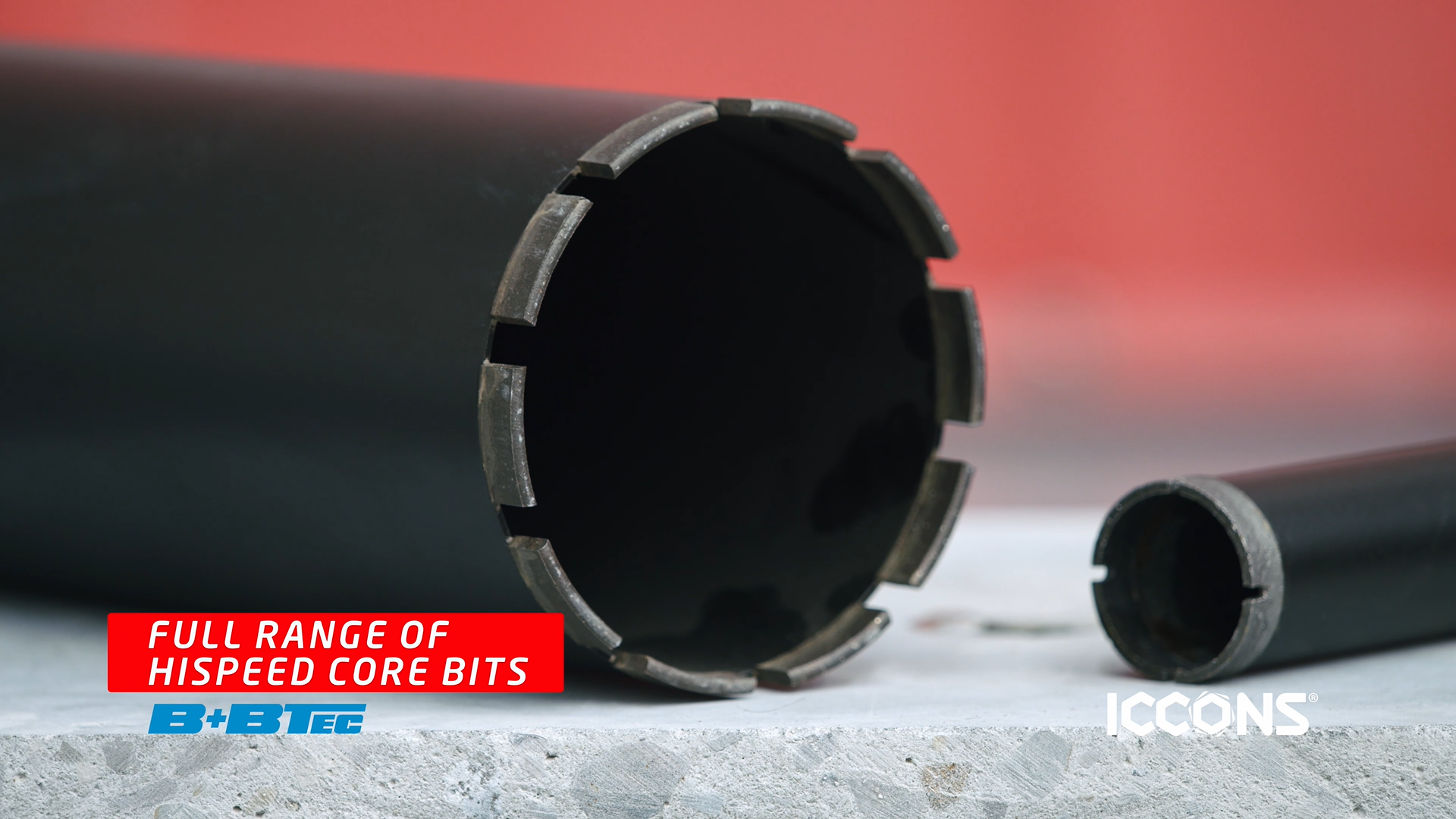

8 Things You Need to Know About Diamond Core Drilling

27 June 2022

1. What is Diamond Core Drilling?

Diamond Core Drilling is a form of drilling which employs a rotary drill with a diamond core tipped bit attached in order to drill the most accurate and quickest hole. Given that diamond is the hardest natural material in the world, this means that it is the perfect tip for drilling into a variety of base materials including concrete, steel and glass.

2. How is a diamond core bit made?

BBTec uses an advanced sintering technology for the manufacturing of the new HiSpeed diamond core bits. Sintering is the process of forming a solid mass of material through heat and pressure without melting to the point of liquefaction. BBTec has developed a new advanced Sintering Technology called SinTec. The combination of SinTec Technology, the development of special bonds and the exclusive use of top-quality diamond crystals has resulted in a unique range of diamond core bits that guarantee an unparalleled drilling speed and long tool life in a wide range of materials.

3. What are the advantages of diamond core drilling over normal forms of drilling?

Diamond core drilling besides being faster and more effective than normal drilling, is far superior in producing high-quality and accurate holes in a safer manner with less noise and less dust production. Given the quality and toughness of the diamond tipped bit, the lifespan of a general bit will far exceed a normal drillbits. Core drilling will also allow the user to perform better in tough or difficult drilling environments given the flexibility and versatility of the tool.

4. How long will a diamond core bit last?

This is completely dependent on multiple variables when drilling including the quality or density of your drilling material, the amount of water you use while drilling, if the user is applying the correct amount of pressure while drilling, how often the specific bit is being used and the quality of the actual diamonds core bit itself. Luckily, ICCONS takes away all the guess work and makes it so easer to not only have the highest quality diamond tools and bits available but to help guide users on these variables and help increase the lifespan of the bits! One of the most useful BBTec Karat 180 features is the dual built in Motor Protection System. The Motor Overload Protection are 7 bright LED’s that visually aid the operation in maintaining optimal bit feed pressure thus preventing motor overload and increasing drilling performance. As well as this, the Pulse™ Electronic Motor Protection System physically alerts the operator of an approaching motor overload by varying the RPM rate up to 6 times before it shuts down automatically. The introduction of both these systems have resulted in increased machine and bit life and allows the operator to always achieve optimal drilling speed and efficiency. The BBTec Karat 180’s key features are unmatched when it comes to today’s core drilling market!

5. How do I correctly use a diamond core drill?

- Assess the environment and check for hazards

- Make sure all relevant PPE is on

- Attach the correct bit size to the drill and make sure the correct gearing setting is chosen, which will allow for the best drilling performance

- Confirm your drilling setup is ready to go – whether it is attaching the stand to the ground, connecting water source, angling your drilling route correctly etc

- Use the Karat soft-start feature to align your bit with your drilling route most accurately

- Make sure to keep your core drill straight while you drill and remember to go slow when you hit tough materials like rebar

- Take the core drill out from the base material when finished and remove the concrete core from inside the core bit

6. What are some key features of the BBTec Core Drill vs Other Core Drills?

- LED Motor Overload Protection System with latest generation RGB LED’s

- 2400W motor with Pulse™ Electronic Motor Protection

- Redesigned mechanical safety clutch manufactured from new special steel composition

- Wet drilling range up to 180mm

- Soft-start option

- Electronic Safety clutch

- 360* rotating water connection

- Data retrieval option to assess drilling use

- Modular Design

- 3 speed gearing for optimal drilling

- 6.8kg, lower weight

7. What are some accessories that will increase the efficiency of diamond core drilling on site?

Drilling Stands – 300mm and 400mm.

i. Water levels for easy machine setup

ii. Anchoring assembly

iii. Engraved drilling depth indication

iv. Quick release slide (300mm only)

v. Quick snap reversible downfeed spindle

vi. Water flow indicator

vii. Column tiltable up to 45* for angled drilling

viii. Transportation wheels

Auto Feed Attachment – suits 180BG and 300 machines

i. LED Display – shows progress and drill depth

ii. Digital depth set and pressure adjustment

iii. Automatically regulates drilling pressure

iv. Automatic retraction when depth is achieved

v. Safety stop button

vi. Easy setup and quick release attachment

vii. Professional grade aluminium motor housing

viii. One lead power supply for both drill rig and auto feed attachment

ix. Provides more drilling metres per core bit

x. One operator can simultaneously monitor more than one machine at one time saving $$$ on labour

Hose 2 GO

i. Constant pressure water supply unit, performs as a bladder rather than a pump

ii. 14 litre capacity means it is ideal for remote worksites or where water is unavailable

Karat 180BG – Second Handle Back Grip

i. Specifically designed for the Karat 180.

ii. Greatly increases operator comfort and stability

iii. Allows for more accurate and efficient use of Karat 180

Karat 180 Shoulder Pad

i. Shoulder Pad for added comfort when operating Karat 180

Core Bit Rescue Tool

i. Designed for the retrieval of stuck core bits with 1 ¼ thread

ii. Tool helps to prevent irreversible damage to expensive diamond core bits when trying to remove from the hole

iii. Allows for stubborn core bits that may be jammed, to be removed.

Karat 180BG Water Collector Ring

i. Water collector ring for a clean work area

ii. Perfect for overhead drilling

8. Where can I purchase a Diamond Core Drill?

If you are interested, please get in touch with us by calling or emailing our details below, or if you prefer - flick us a message on our social's below!

As always, follow us on Instagram, Facebook and LinkedIn to stay in touch with other relevant updates!

Should you require anymore information – please don’t hesitate to get in touch with our technical experts via [email protected] or alternatively call us on 03 9706 4344.

Need further support?

Get in touch with our technical experts today

Don't forget to follow us on Facebook, Instagram and LinkedIn to stay in touch with other relevant updates!

Latest articles

-

20 May 2025

20 May 2025ICCONS Stands Proud as a Home-Grown Brand

With many iconic Australian fixing and fastening brands now in the hands of offshore giants, ICCONS stands firm. Australian owned and operated.

Read More -

30 April 2025

30 April 2025What's New 🔥 New Recyclable Trade Pack & Trade Tub Packaging!

ICCONS® Takes Another Step Towards Sustainability with New Recyclable Packaging!

Read More -

5 March 2025

5 March 2025Expert Tips on Seismic Anchoring: Insights from ICCONS and KUSCH

The importance of proper selection and installation of concrete screw anchors, including ICCONS’ Thunderbolt® PRO, in seismic-rated applications.

Read More