If you own or operate a construction supply outlet, you may be eligible to supply ICCONS range of construction fastening supplies at wholesale prices!

- Log In

- Sitebox

- Contact

- Find a dealer

-

Anchoring

Anchoring

- Screw Bolts

- Thru-Bolt Stud Anchors

- FM753 - Heavy Duty Through Anchors

- ATS-EVO Heavy Duty Anchors

- STA-EVO Heavy Duty Anchors

- Hangerz

- Drop-In Anchors

- Suspension and Tie Wire Anchors

- Sleeve Anchors

- Panel Brace Anchors

- Friulsider Nylon Anchors

- Metal - Light Duty

- Nylon - Light Duty

- Plasterboard and Hollow Cavity Wall Anchors

- Plastic Wall Plugs and Spaghetti

- Strike Anchors

-

Pipe Clamps

Anchoring

-

Cast-In Anchors

Anchoring

- Shims and Other

-

Hollow Section Fittings

Anchoring

-

Adhesives

Adhesives

-

Nailing

Nailing

- Rivets

-

Screws

Screws

-

Self Drillers

Screws

- Self Drilling Bugle Head

- STET Aesthetic Architectural Tamper Resistant Screw

- Self Drilling Button Head

- Self Drilling Countersunk Head

- Self Drilling Countersunk Wing

- Self Drilling Flathead

- Self Drilling Hex Head

- Self Drilling Mushroom Head

- Self Drilling Pan Head

- Self Drilling Trade Packs

- Self Drilling Trade Tubs

- Self Drilling Wafer Head

- Self Drillers

- Type 17

- Collated

-

Decking

Screws

- Needle Point

- Chipboard

- Cyclonix

-

Painted Screws

Screws

- Painted - Needle Point Hex Head

- Painted - Self Drilling Button Head

- Painted - Self Drilling Flathead

- Painted - Self Drilling Hex Head

- Painted - Self Drilling Multiseal - 14 Gauge

- Painted - Self Drilling Trade Packs

- Painted - Self Drilling Trade Tubs

- Painted - Self Drilling Wafer Head

- Painted - Type 17 Cyclonix - 14 Gauge

- Painted - Type 17 Hex Head

- Painted Screws

- Muro - Collated Screw Solutions

-

Self Drillers

-

Drilling

Drilling

- Drilling - SDS Plus

- Drilling - SDS Max

- Dustless Drilling

-

Drilling Power Tool Accessories

Drilling

- Countersinking / Pre-Drilling Accessories

- Impact Fastdrive - Bit Holders

- Impact Fastdrive - Bit Kits

- Impact Fastdrive - Insert Bits

- Impact Fastdrive - Nut Setters

- Impact Fastdrive - Power (Double Ended) Bits

- Impact Fastdrive - Power Bits

- Standard Fastdrive - Bit Holders

- Standard Fastdrive - Insert Bits

- Standard Fastdrive - Nut Setters

- Standard Fastdrive - Power Bits

- Impact Sockets

- Drill Attachments

- Tile Bits

- Ratioquick Core Bits and Accessories

- Drilling Power Tool Accessories

- Metal / Wood / Concrete Kits

-

Diamond

Diamond

- Tools

-

Other

Other

- Support & Downloads

- Partners

- Careers

- About

Dealer Login

Types of Screws in Construction

02 December 2024

When it comes to construction, whether you’re a professional or a DIY enthusiast, using the right screw is crucial to ensuring the longevity and success of your project. From securing heavy-duty materials to assembling furniture, the right screw can make all the difference. In this article, we explore the various types of screws used in construction, their specific applications, and how to select the right one for the job.

For ICCONS full range of screws head to https://www.iccons.com.au/categories/screws

The Role of Screws in Construction

Screws play a critical role in modern construction by providing the strength and stability needed to fasten materials securely. Whether you are building a home, installing drywall, or creating outdoor decking, using the correct type of screw ensures that your projects are properly fastened for a professional finish and to minimise failures over time. Choosing the wrong screw can lead to complications such as loose connections, a poor finish, rust, or even structural failure in some instances. With a wide variety of screws available, it’s essential to understand their differences and how they apply to different materials and environments.

Common Screw Head Types

Screw head types are designed for different applications and finishes. Selecting the appropriate head type is critical for proper installation, application efficiency and ensuring your project is a success.

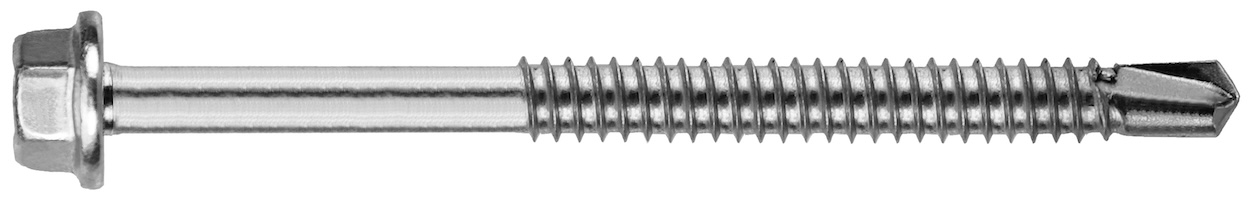

Hex Head: A common six-sided head used for numerous high torque applications, commonly installed with a nut-setter. Hex head screws are found in ¼” , 5/16” or 3/8” drive size, in 8#, 10#, 12# & 14#.

Wafer Head: A thin, wide head that provides a large surface area for better clamping Force. Normally with a Phillips #2 recess drive Wafer head screws are often used in light timber, steel applications.

Bugle Head: A tapered, round head screw that sits flush with the surface. Normally with a Phillips #2 or 5mm Internal Hex drive. Bugle head screws are ideal for drywall screws to reduce surface damage.

Flat Head: A thin head that is designed to sit flush with the surface for a clean finish. Normally with a Phillips drive #2 or #3 depending on screw diameter and application.

Countersunk: Similar finish to a flat head but with an under-head taper, ensuring screw strength the screw sits flush or below the surface, commonly used in woodworking applications.

Button Head: A domed head with a wide bearing surface, often used for thin clamping applications or decorative finishes.

Pan Head: A rounded, domed head with a flat bearing surface underneath, providing a strong hold for general purposes.

Architectural Head: A clean, low profile Hex head often used for visible applications where an aesthetic appearance is important.

Screw Thread Types and their Applications

The thread of a screw is crucial to how well it grips and secures the fixture and substrate materials. Below are the two most common thread types:

Coarse Thread: Ideal for use in wood, coarse threads, and thin metals to provide better grip and hold by biting into the material. They are less likely to strip the material and can be used in a variety of applications.

Fine Thread: Fine-thread screws are better suited for thicker metal where the self-tapped thread has greater purchase resulting outstanding load performance.

Screw Materials and their Uses

Selecting the right material for your screw is essential for ensuring its longevity and suitability for different environments:

Carbon Steel: Carbon steel screws are a the most common choice for general construction due to their strength and durability. Paired with the right coating (zinc, mechanical galvanised, etc), carbon steel screws can provide outstanding service life. However, it is important to select the correct coating to minimise the occurrence of corrosion when exposed to the elements.

Stainless Steel: Known for their excellent corrosion resistance, stainless steel screws are perfect for outdoor and marine environments. They are commonly used in decking, fencing, and other external applications where moisture and high corrosion may be an issue. Check out our stainless-steel screws for outdoor projects.

Understanding the properties of each material ensures that you use the right screw for the job, particularly in environments where corrosion is a concern.

Choosing the Right Screw for the Job

Selecting the correct screw involves considering the material, the environment, application characteristics and the load requirements of the project. Here are some general guidelines:

Wood Projects: Use coarse-thread screws for wood as they provide a firm grip while minimising splitting of the material. Head style is completely dependent on your required finish.

Metal Projects: Fine-thread or coarse thread screws are best suited for metal, depending on the thickness of the metal, providing a secure hold without the need for pre-drilling in most cases. Head style is completely dependent on your required finish.

Outdoor Projects: Stainless steel or mechanically galvanised screws should be used outdoors due to their corrosion resistant characteristics when encountering moisture and the elements.

The gauge (diameter) and length of a screw are equally important. Make sure to refer to manufacturer guidelines on screw suitability for your application.

Frequently Asked Questions

What’s the difference between self-tapping and self-drilling screws?

Self-tapping screws require a pilot hole and create their own thread as they are driven into the material, while self-drilling screws create their own pilot hole, making them ideal for metal applications.

How do I know what screw size to use?

The size you need depends on the thickness of the material and the load the screw must bear. Ensure you follow manufacturer screw guidelines to select the right screw for your application.

What screw type is best for outdoor construction?

Stainless steel screws are ideal for outdoor projects due to their corrosion resistance. View our range of outdoor screws for more options.

Can screws be reused?

In most cases, screws should not be reused as they may lose their structural integrity after being removed, which could compromise their performance.

Associated Products

ICCONS also provides a wide range of tools and accessories to help you complete your project. From driver bits, countersinking drill bits and other installation tools, you’ll find everything you need for a professional finish.

Conclusion

Whether you’re a seasoned professional or tackling your first DIY project, choosing the right screw is essential for ensuring your project’s success. By understanding the types of screws available and their applications, you can ensure that your work is secure, durable, and built to last.

Explore ICCONS' full range of screws and fasteners today and ensure that your next project is completed with precision and confidence.

Need further support?

Get in touch with our technical experts today

Don't forget to follow us on Facebook, Instagram and LinkedIn to stay in touch with other relevant updates!

Latest articles

-

30 April 2025

30 April 2025What's New 🔥 New Recyclable Trade Pack & Trade Tub Packaging!

ICCONS® Takes Another Step Towards Sustainability with New Recyclable Packaging!

Read More -

5 March 2025

5 March 2025Expert Tips on Seismic Anchoring: Insights from ICCONS and KUSCH

The importance of proper selection and installation of concrete screw anchors, including ICCONS’ Thunderbolt® PRO, in seismic-rated applications.

Read More -

3 February 2025

3 February 2025What's New 🔥 FIXFAST Subfloor Adhesive

ICCONS® introduces FIXFAST Subfloor Adhesive, designed to deliver a durable, long-lasting bond for subfloor installations, reducing the risk of squeaky floors while enhancing overall floor stability.

Read More